Your Cart is Empty

Polystyrene has for a long time been used to form and block out shapes in concrete. Increasingly these requirements are becoming more complex as cnc profile cutting and cnc routing become more affordable, and more capable. Some of our recent work can be seen here.

Foam Sales was delighted to be part of Curtin University's recent upgrade to their bike amenities on campus. The uni is very well situated for bike access, and has done a lot to encourage staff and students to make use of the many multi-use paths both on site and in the surrounding suburbs.

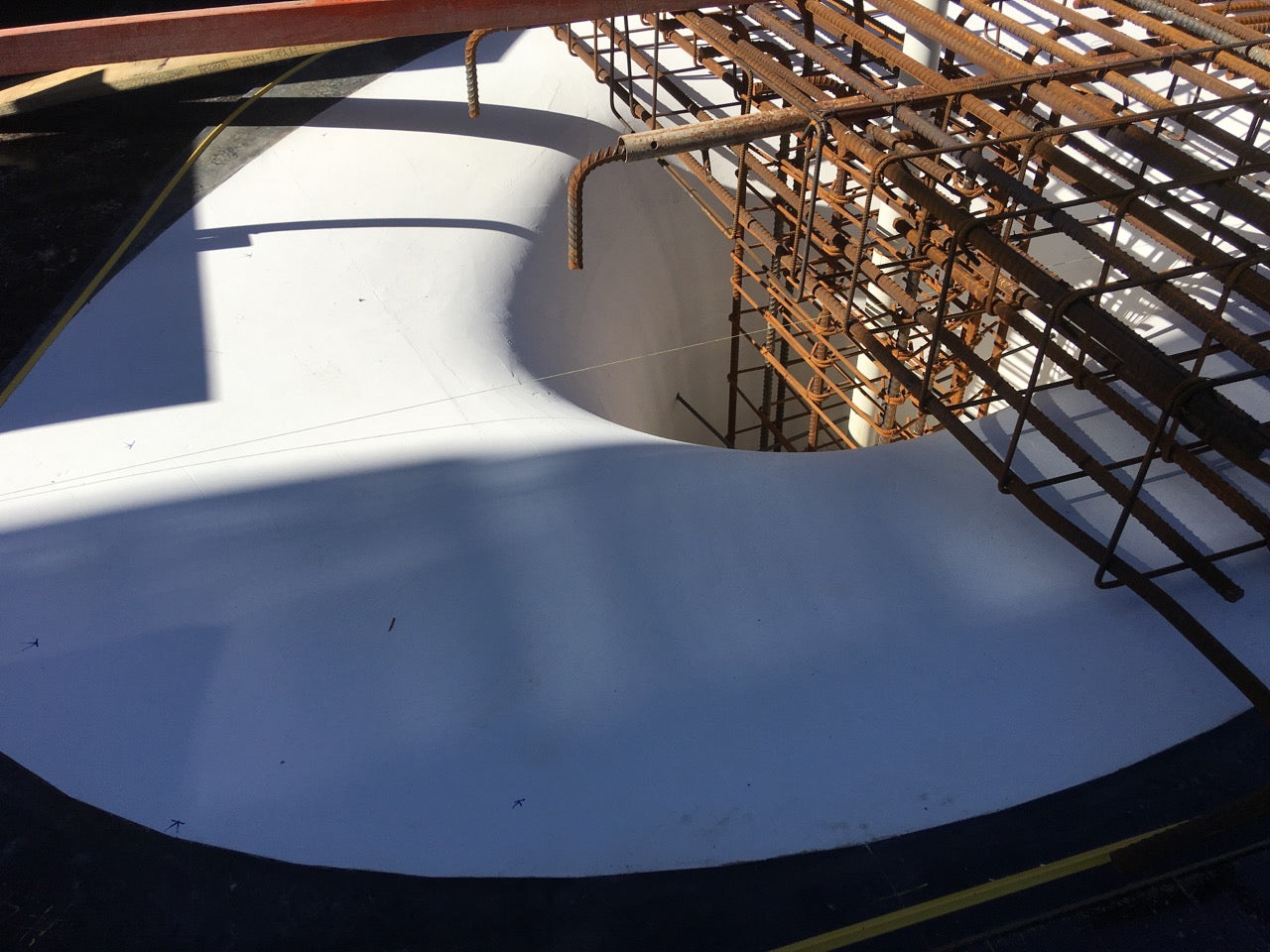

Curtin's development was a multi-level bike parking area, featuring complex concrete shapes that could only be cast using polystyrene moulds. A central concrete column provides structural support for the first floor, and rounded concrete guard rails snake around the edges of the first floor - both of these concrete elements are sloping and irregular, requiring precision cutting of custom moulds.

Curtin's development was a multi-level bike parking area, featuring complex concrete shapes that could only be cast using polystyrene moulds. A central concrete column provides structural support for the first floor, and rounded concrete guard rails snake around the edges of the first floor - both of these concrete elements are sloping and irregular, requiring precision cutting of custom moulds.

With the help of one of our partners seen here we turned out perfect moulds that were cut in multiple blocks and glued together on site to allow for easier transportation.

Recently we shaped this dome mould for the new Chapel at Karrakatta. It too is made from several blocks of precision-cut polystyrene which we glued together and finished with a fine layer of plaster filler to give the perfectly smooth finish required by the builder.

The three dimensional curve form here is one of many polystyrene forms we make for hand rails, edge forms and curving concrete structures. We cut the polystyrene cylinder for the Water Corporation, fitted it with the steel plates top and bottom and had the whole item coated in polyurethane for long term protection in water. It serves as a flotation buoy for instrument readings being taken on dam surfaces.

Comments will be approved before showing up.